Coffee is a sensory item. It picks up dampness, oxygen, smells, and heat much faster than a lot of pantry staples, and its flavor lives or passes away by tiny information in storage space and transportation. When you try to ship it extra responsibly, trade-offs show up all over. One of the most robust bag movies often tend to be the least recyclable. Compostable options can break down in humid climates. Lightweight mailers lower freight exhausts, yet they might fold shutoff bags and contusion beans. I have worked through these trade-offs with roasters from Melbourne to Perth and with e‑commerce groups that ship thousands of parcels a week. The goal is a delivery program that protects freshness, trims waste, and remains honest regarding costs and constraints.

Why packaging design is the keystone

Good intentions untangle if the bag stops working on a customer's counter. Roasted beans launch CO two for days, and oxygen ruins aroma complicateds that you spent hours coaxing out of the roast contour. Packaging needs to let gas out while keeping oxygen and wetness away, and it requires to do that throughout various climates and transit times. Press also difficult for single-material simplicity, and your beans can stagnant faster than your brand name voice can explain it. Go overboard on barrier laminates, and you develop waste that community systems can not handle.

The sweet area is hardly ever a solitary solution. It is a combination of a high-barrier key bag, a protective outer, and an end-of-life path that customers understand. Coffee roasters often believe first regarding values at beginning, which is important, yet the lifecycle after toasting is where consumers touch your sustainability declares daily. Just How your Coffee Beans Delivery parcel arrives frameworks their experience of your item and your values.

What "green" actually means in coffee shipping

Eco-friendly is not a solitary statistics. The product packaging that looks virtuous on a product web page can fail when you track the numbers. A defensible technique evaluates a minimum of 4 measurements and accepts that not every combination is possible for each roaster.

- Barrier performance vs. product simplicity: High barrier safeguards flavor and reduces food waste, which typically surpasses packaging discharges. Yet high-barrier films are generally multi-layer and more challenging to recycle. Choose the minimum barrier that preserves service life for your distribution home window, not a theoretical year on a shelf. Freight effectiveness: Lighter and smaller parcels indicate fewer trucks, reduced air cargo emissions, and less gas per kg of coffee delivered. Wisely created bags and mailers can cut volumetric weight by 10 to 25 percent. Real end-of-life outcomes: A reusing icon that a council does not accept is cinema. Compostable product packaging that needs a commercial center is not practical if your consumers just have home garden compost. Map your clients' real options, specifically for Coffee Beans Delivery Australia where local systems vary by state. Operational realistic look: If a bag sealer needs continuous recalibration to shut a compostable film, your group will certainly revert to old stock during optimal period. The very best lasting choice is one your production line can run daily without drama.

These elements add up to complete impact. The least inefficient parcel is the one that shields beans so people complete the bag, shows up with very little damage, and enters a waste stream that really exists.

Primary bags: what jobs, where it stops working, and how to choose

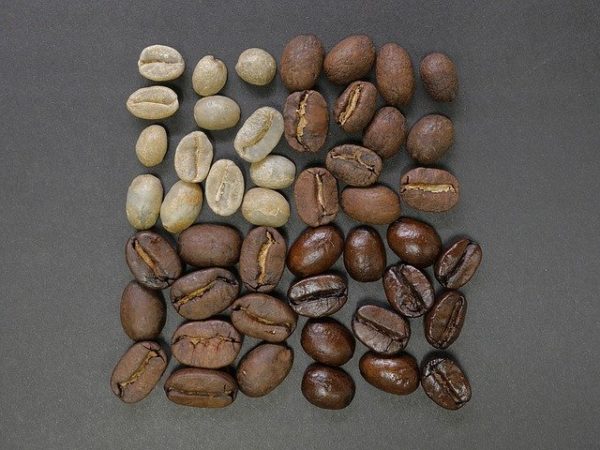

Most specialty roasters make use of gusseted or flat-bottom bags with a one-way valve. The argument relaxes the movie. Three families dominate, each with staminas and pitfalls.

Polyethylene monomaterial with EVOH: Makers bond layers of PE with a slim EVOH barrier, plus a shutoff. These bags reuse even more quickly as soft plastic where programs exist, and they seal consistently on typical impulse sealers. The barrier is great, not great. For a two to six week shipment and usage cycle, they execute well if you roast fresh and ship quick. In really damp or warm climates, oxygen ingress climbs, and a 250 g bag can shed top notes before the last cup.

Multi-layer metallized films: Believe animal or BOPP laminated to a metallized layer with PE sealer. Obstacle is excellent, oxygen access gauged in portions of a cc per square meter each day. Beans remain brighter for longer, which matters for slower-moving SKUs or long-haul shipping. The trade-off is recyclability. Many councils treat them as general waste. If you select this course, decrease product where feasible with slimmer walls and smaller valves, and make the external system minimal.

Compostable films, typically PLA with a plant-based sealant: Succeeded, these really feel great in the hand and message a clear intent. In practice, they require focus. Seal windows are narrower, particularly on high-speed lines. Valves can leak under warm, and barrier performance decreases in damp problems. Home compostable insurance claims differ; many call for industrial composting. In seaside Australia or the tropics, humidity can swell films and crinkle zippers. If your clients live near facilities that accept these bags, they can work, however test aggressively throughout seasons.

If you pressed me for a default that balances performance and obligation for a broad Coffee Beans Delivery program, I would certainly start with a high-barrier PE monomaterial bag with EVOH and a Lab-tested valve, after that tune from there. It reuses in soft plastic streams where offered, seals conveniently, and secures most coffee roasts for the time it requires to consume alcohol them.

The valve inquiry and degassing routines

Valves are not optional for fresh roast shipped swiftly. If you roast Monday, ship Tuesday, and the parcel beings in a van midweek, CO ₂ accumulation can rupture seals or distort the bag. Miss the shutoff only for fully rested beans or nitrogen-flushed packs meant for retail racks. Select valves with low oxygen transmission and confirm positioning so the warmth seal does not endanger the seat.

Rosters suggest about pre-degassing. For shipment, a brief remainder prior to getting, four to 8 hours for lighter roasts and two to four for darker, lowers bag ballooning and panel tension. You can still ship within 24 hr of roast, and the coffee take advantage of a day or 2 even more rest in the client's kitchen.

The outer plan: where you win or lose emissions

A bag that survives your roastery needs a 2nd shell to survive sorting hubs and front doors. This is where you can eliminate a surprising quantity of waste without touching flavor.

Rigid cartons vs. mailers: For solitary 250 g or 500 g shipments, a well-sized padded mailer shields without a box. Two or more bags, or 1 kg formats, take a trip much better in a container. Double boxing rarely aids and inflates volume. Usage carton sizes that hug your SKUs. Half-empty boxes waste gas and invite crushing.

Padding: Lots of roasters default to bubble wrap. For beans, the external bag and a snug fit do most of the work. Paper fill, 1 or 2 crumpled sheets, avoids corner crushes and soaks up shocks. Pick recycled material and stay clear of shiny finishes. If you must make use of bubble for global paths, select recycled-content movie and maintain lengths short.

Water-activated tape vs. plastic tape: Gummed paper tape bonds to containers with a solid seal that tolerates moisture. It is not excellent in wet-season last-mile courses on the coastline, however it outmatches acrylic tape in the majority of examinations and prevents plastic fragments in reusing streams.

Returnable mailers: In dense urban markets with repeat clients, returnable pouches can work. The adoption rests on tidy, simple return steps and an incentive. Without both, return prices waste away listed below 20 percent, and the footprint worsens.

Labeling that does not weaken recyclability

Small things damage recycling streams. A metallic label on a recyclable PE bag can develop contamination problems, and a thick PET window in a paper mailer does the same. Utilize paper tags with water-based inks on cartons and mailers. On bags, choose tags that match the base material whenever feasible. For monomaterial PE bags, a PE label maintains it in one family, though the adhesive still matters. If you need to utilize paper on film, keep labels small to minimize disturbance and position them far from the seal location to stay clear of micro-leaks.

How shipment rhythms form your packaging choices

Packaging lives inside your operations and your pledges to customers. If you roast to get two times a week, your beans are fresher on arrival, and you can use a somewhat lighter barrier. If you roast when a week and ship across the nation, you need more security. For Coffee Beans Delivery Australia, think about the routes:

East coast city to city: 2 to 3 days is regular. Summertime temperature levels inside vans can hit 40 to 60 ° C. Obstacle and seal honesty issue more than cushioning. Select mailers with light insulation if you ship during heatwaves, or routine dispatch very early week to stay clear of weekend break depots.

East to west, Sydney or Melbourne to Perth: Include two to four days, in some cases a lot more. Here, more powerful obstacle bags pay off, and cartons lower compression threat in long consolidations.

Regional and remote: Transit times differ hugely. Consider nitrogen flushing for a subset of SKUs delivered to remote postal codes, or plainly message roast days and ideal usage windows so consumers can plan. Assurance less, delight more.

Subscription programs decrease variability. You can roast in rhythm with delivery schedules, pack while beans are at predictable degassing stages, and ship with cardboard inserts customized to your SKUs. Predictable box dimensions allow you buy products wholesale and reduce changeovers that cause waste.

The small print on compostables and reusing in Australia

The phrase "Coffee Beans Delivery Australia" covers regions with wildly various facilities. Soft plastics collection via grocery stores has stopped briefly and restarted in fits. Council kerbside programs vary by state and pilot. Industrial composting accessibility is unequal. Before you brand a solution as green, call waste authorities in your vital shipment areas and ask three concerns:

- Can residents place this particular product in kerbside recycling or green waste? Not theoretically, however in practice, today. If not, is there a drop-off program within sensible distance and consistent hours? What contamination threats does your product packaging position if consumers think wrong?

Brands that release a clear disposal flowchart for their top 3 consumer regions see fewer mad e-mails and higher conformity. Include a QR code that finds the customer's place and serves disposal directions matched to local programs. Customers appreciate being treated like adults and will compensate clarity.

Reducing returns and breakage is a sustainability strategy

Every returned parcel doubles the freight impact and often causes beans past their ideal. One of the most sustainable renovation lots of Coffee Beans Delivery procedures can make is simple: ship orders properly, promptly, and with tough labels. Moisture-resistant shipping tags with solid adhesives minimize shed parcels in humid months. Ink that does not smudge in light rain saves telephone call. A tidy pick-and-pack process with weight checks captures mispicks prior to they leave the building.

I have actually seen returns drop by a third when a roaster included a 30-second consider confirmation action and printed roast dates in bigger kind. Less returns suggest fewer replacement shipments, fewer distressed subscribers, and less waste that can not be meaningfully recovered.

Courier selection and transmitting choices

The provider you select establishes the flooring and ceiling for damage rates and discharges. Some messengers handle satchels far better than cartons, others the opposite. A quick A/B test throughout 2 or three carriers throughout your busiest month tells you which delivers fewer smashed parcels and faster transit. Maintain score, not anecdotes.

Carbon-offset programs can be component of the tale, but they are not a license to deliver badly. Better is a directing technique that reduces courses. For nationwide shipping, gratification from 2 nodes can cut typical last-mile range by 20 to 40 percent. That might indicate a tiny satellite in Brisbane to serve Queensland and north NSW while your primary roastery ships south and western. Balance the gains against the complexity of supply splits and quality control at numerous sites.

A note on quality home windows and customer education

Eco-friendly methods function best when clients handle beans well after arrival. A fast card in the parcel or a post-purchase e-mail can raise satisfaction and minimize insurance claims. Keep it practical and short: shop in a cool, dry cupboard, keep the bag whized in between uses, prevent the refrigerator unless the bag is secured and you are portioning to freeze, and objective to complete within three to 4 weeks of roast for most espresso profiles. If you offer filter roasts with longer optimals, inform them.

Clear roast days beat unclear set codes. Openness constructs trust, and it decreases the urge to over-engineer service life with hefty packaging.

When you should consider nitrogen flushing

For export or for domestic paths that frequently surpass a week en route, a light nitrogen flush can be a better ecological choice than updating to a non-recyclable ultra-barrier laminate. Nitrogen displaces oxygen inside the bag, slows staling, and does not transform the coffee's chemistry in the mug. You need an easy arrangement: a food-grade nitrogen cyndrical tube, a regulatory authority, and a flush nozzle incorporated right into your bagging line. Validate with oxygen meters, not guesswork. If you can hold interior oxygen below 2 percent, you expand flavor security without difficult films.

This is not necessary for a lot of metro shipments. It beams when shipping 1 kg bags to remote postcodes or sending out beans to hot warehouses.

Real numbers: where the effect hides

I have viewed roasters reduced mailer dimension by 15 percent and conserve 8 to 12 percent on products emissions per parcel due to lower volumetric weight. Switching bubble cover for 2 sheets of 70 gsm recycled paper minimized plastic mass by 20 to 40 grams per parcel without any measurable rise in damage. Moving from a hefty metallized movie to a PE monomaterial bag cut 6 to 10 grams per 250 g pack. These sound like rounding mistakes till you multiply across tens of countless deliveries per year.

The opposite is also real. A bad valve that leaks raises oxygen access and can cost you a warehouse pallet of stagnant stock. A weak carton that caves at the edges might boost damage by a portion factor that wipes out any type of product cost savings. Test, procedure, adjust.

Building a useful roadmap

Ambition is great. Roadmaps that your team can implement are much better. The course I recommend to roasters that want the most effective Coffee Beans Delivery experience without greenwashing normally complies with a straightforward progression.

- Establish a standard: Audit your existing packaging expense of products, damage rates, returns, and transit times by course. Weigh parcels and note measurements. Track oxygen inside bags on day 1, 7, and 21 for your leading SKUs. Improve fit and freight: Right-size cartons and mailers first. Minimize void space. Change to paper padding when protection continues to be adequate. This commonly produces the biggest, fastest discharges win. Optimize the bag: Trial a monomaterial high-barrier alternative versus your current film for 2 months. Measure taste stability, seal integrity, and consumer responses. If security holds for your shipment home window, adopt it. If not, have metallized movies to SKUs that truly require them. Clarify disposal: Release region-specific advice. Add QR codes on the bag and the carton. Use labels that match the base product where feasible. Tune operations: Include evaluate checks, improve label toughness, and align roast and dispatch routines to decrease weekend warehousing. Evaluation carrier performance quarterly. Explore advanced alternatives: Nitrogen flush for long paths, returnable product packaging in thick collections, or a second satisfaction node if volume and geography support it.

The Australian angle: climate and councils

Australia adds appearance to every line of this strategy. Warm events are sharper, distances are much longer, and local recycling assistance modifications much faster than your printers can keep up. When your Coffee Beans Delivery Australia program offers customers in Darwin, Hobart, and Geraldton, you are managing three climates and several governing regimes. A bag that performs in completely dry inland warmth might fail in seaside humidity. If your client base stretches throughout the nation, think about seasonal packaging modifications. Summertime runs could utilize a greater obstacle or an extra inner layer for long westbound routes. Winter months runs can lean into lighter options.

Stay connected in to state-level packaging regulations and the Australian Packaging Agreement Company's updates. Not every stylish product satisfies the "recyclable in method and at scale" examination. Clients appreciate a straightforward note when programs alter. If soft plastics collection stops briefly, claim so, and point to the best available alternative, even if that is basic waste for a period. Reliability outlasts any kind of solitary packaging choice.

Pricing, margins, and consumer perception

Eco-friendly selections set you back cash, sometimes in materials, frequently in labor. Clients will certainly pay a little bit much more for coffee they trust, specifically customers who value uniformity. What they will not endure is complication or fragility. If you need to include 20 to 40 cents to cover far better products, be explicit about what the modification provides: lowered plastic mass, simpler recycling, fewer damaged parcels, more powerful aroma on day 10. Mount it around quality and duty with each other, not guilt.

Bundle shipping thresholds to award efficient orders. A solitary 1 kg bag normally travels better than four 250 g bags, uses less material per gram, and frequently tastes much better at week two than a https://jsbin.com/suliwiceve tiny bag at day 7 after duplicated openings. A tiny rate break nudges habits in the best direction.

A short word on ground coffee

Ground coffee is a lot more susceptible than entire beans. If you offer grinding, pair it with one of the most protective alternative you have. For city shipments within 2 days, a strong monomaterial bag with a valve can be enough if you grind to purchase and secure immediately. For longer paths, a heavier barrier or a nitrogen flush decreases staling. Motivate clients to order smaller sized quantities more regularly if they insist on ground. Even better, enlighten on basic hand grinders that transform the entire equation in your favor.

Quality control that respects taste and the planet

Taste panels are sustainability devices. If your packaging fine-tune preserves aromatics and acids much longer, consumers will squander much less coffee at the end of the bag and reorder more with confidence. Adjust with cuppings at days 3, 7, 14, and 21 across product packaging variations. Tape actual taste notes, not just numbers. Validate with oxygen meters and drop testers, however depend on your taste buds to determine what concessions are acceptable.

I have actually sat in sampling spaces where a beautiful compostable pouch tasted like the ideal choice up until day 10, when sweetness diminished a cliff compared to a slightly less virtuous movie. That does not make compostables wrong, however it does imply you ought to guide them toward short-haul clients that consume rapidly, not towards slow-moving present loads going across the country.

Bringing it all together

A legitimate environment-friendly Coffee Beans Delivery program is not a single jump. It is the sum of little, validated renovations that secure flavor, lower waste, and fit your operations. Ground your choices in testing instead of cases. Go for products that match genuine disposal paths your customers can gain access to. Right-size your parcels, choose carriers on performance, and align your roast routine to your routes. Know when to pick a more powerful barrier because it stops food waste that dwarfs a couple of grams of plastic. Know when a monomaterial bag and a far better mailer deliver comparable high quality with a lighter footprint.

Roasting well is effort. Obtaining that job to somebody's cooking area intact, tasty, and with a lighter touch on the world is another craft. Treat it with the exact same treatment you apply to bill temperature and development time, and your clients will taste the distinction long after the parcel strikes the doorstep.